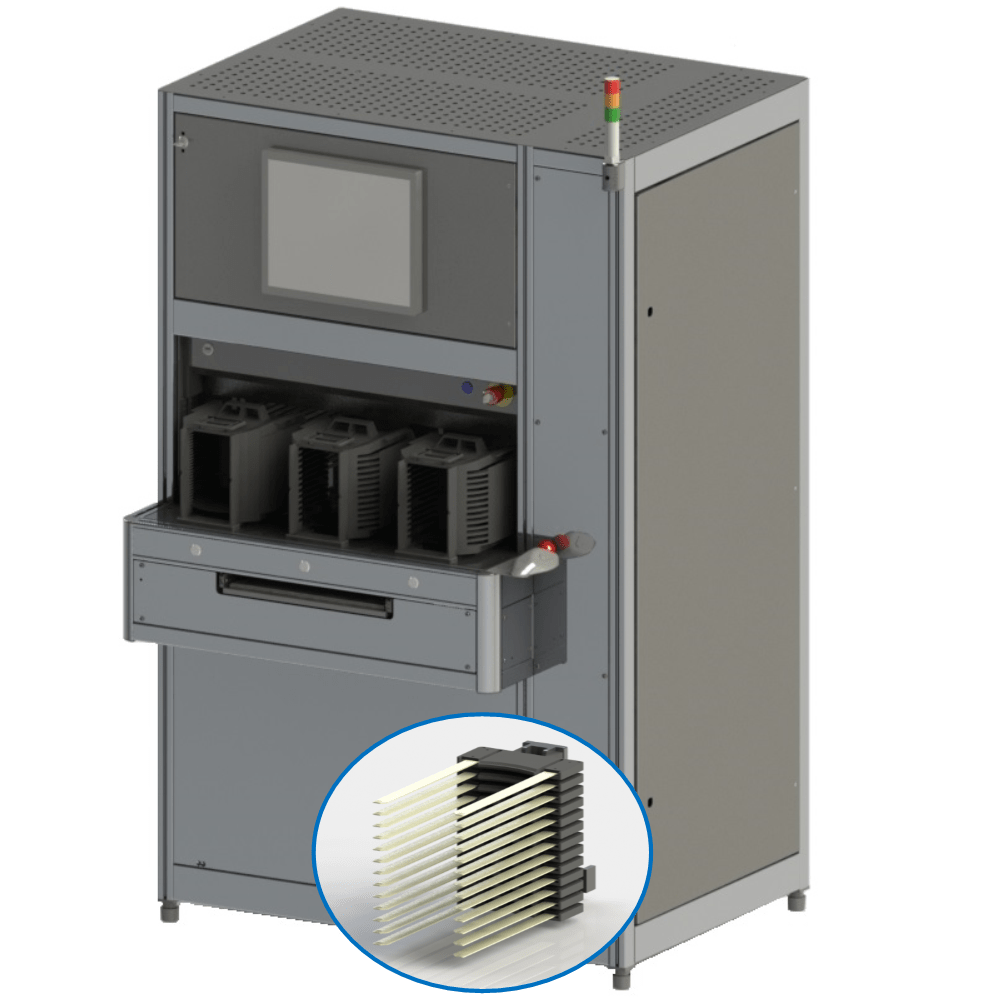

The HBT Stand Alone systems are Horizontal Batch Transfer machines allowing transfer in batches, batch splitting and merging.

This equipment is mainly required when the vertical batch transfer is unsafe, because of two main reasons:

⇒ Significant warping of the wafers, with high risk of wafer breakage on batch splitting and merging transfer;

⇒ Cassette with insufficient or absent narrow bottom slot, when the position of the wafers in the slots does not allow them to be picked up correctly.

The HBT Stand Alone systems are the best solutions to transfer your wafer batches safely, even with warped wafers or special cassettes.

To transfer wafer batch, the machine is equipped with a gripper of 13 postions, with 2 edge contact ceramic finger for each position that ensures accurate and safe handling of wafers.

Transfer available:

Thanks to cassette kinds detection system and wafer mapping system, the user only has to drop his cassette to the load ports according his transfer needs, select the thickness of the wafer to transfer and launch the mapping. Once the mapping is done, the machine will only propose to the user the possible transfer to perform via the interface. The User only has to click on the interface to launch the requested transfer.

Moreover, the HBT 3LP systems can be used on local mode or on remote mode thanks to SECS-GEM communication to the fab host (E30), and meet the requirements to be loaded/unloaded by AVG/RVG, providing a E84 connection for each load ports to install PIO. (optional)

Key system features

Standard features

Specifications

Options

Interface

Facilities and Requirements